One of Hottest for General Purpose Cutting Blade - Diamond Squaring Wheel(segment) – JIAYAN

One of Hottest for General Purpose Cutting Blade - Diamond Squaring Wheel(segment) – JIAYAN Detail:

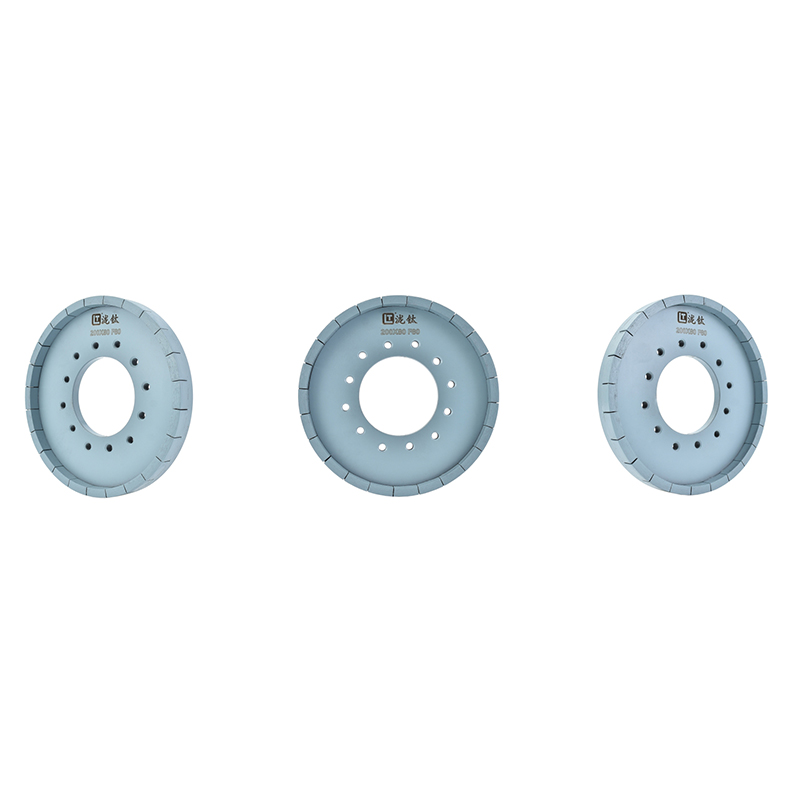

After the diamond calibrating roller processes the porcelain tile, producing a smooth surface with fixed thickness, the diamond segment grinding wheel can perform milling with excellent efficiency. It can be used for big size glaze ceramic tiles,porcelain tiles and polished porcelain tiles.Diamond dry edging wheel is mainly used for rough grinding, fine grinding and trimming of polished tiles, antique tiles and microcrystalline tiles. It mainly has the following characteristics: no black edge, good sharpness, long service life, low noise, Fast heat dissipation and less dust. It is very good to ensure the verticality and size requirements of the processed products, and will not collapse or collapse. The production process is strictly controlled and the product quality is stable. Choose reasonable formula and particle size matching for different brick quality. Products with various installation sizes can be manufactured according to customer requirements.

1.Dry and wet dual-use operation is convenient for dry grinding without burning the wheel

The service life of single-layer brazed diamond products is 2~3 times that of electroplated products. When cutting stone, dry grinding can be done without adding water, and the service life of single-layer brazed diamond products is longer. The grinding efficiency of single-layer brazed diamond products is 1~2 times that of electroplated products.

2.The grinding speed is fast and the work efficiency is effectively improved

Brazed diamond products do not delaminate or drop teeth during use, and the performance is safe and stable,It will not cause secondary pollution to the environment during use, and is a national green product,This product is made of imported diamond, super wear-resistant

3.Usage

The abrasive tool is used for processing granite, marble, concrete, ceramic tile, glass-ceramic, etc. 39353 The production formula of the improved composite bottom material of diamond grinding stone developed by Zhongyuan Institute of Technology is the processing technology of diamond grinding tools. The new formula process eliminates the phenomenon of bending (Bend) deformation, cracks, and delamination during high-temperature sintering, and ensures product quality. A new composite bottom material for diamond grindstones that can effectively prevent bending deformation, cracks or delaminations from existing diamond grindstone production technologies.

| DESCRIPTION | SPECIFICATION | WIDTH | HEIGHT |

| DIAMOND SQUARING WHEEL(SEGMENT)

|

Φ200 | 10 | 13 |

| Φ250 | 10 | 13-16 | |

| Φ300 | 12 | 14-16 |

Product detail pictures:

Related Product Guide:

Excellent 1st,and Client Supreme is our guideline to deliver the ideal provider to our prospects.Nowadays, we have been seeking our best to become certainly one of the most effective exporters in our discipline to meet shoppers more require for One of Hottest for General Purpose Cutting Blade - Diamond Squaring Wheel(segment) – JIAYAN , The product will supply to all over the world, such as: Iceland, Slovakia, UK, We believe that good business relationships will lead to mutual benefits and improvement for both parties. We have established long-term and successful cooperative relationships with many customers through their confidence in our customized services and integrity in doing business. We also enjoy a high reputation through our good performance. Better performance will be expected as our principle of integrity. Devotion and Steadiness will remain as ever.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.