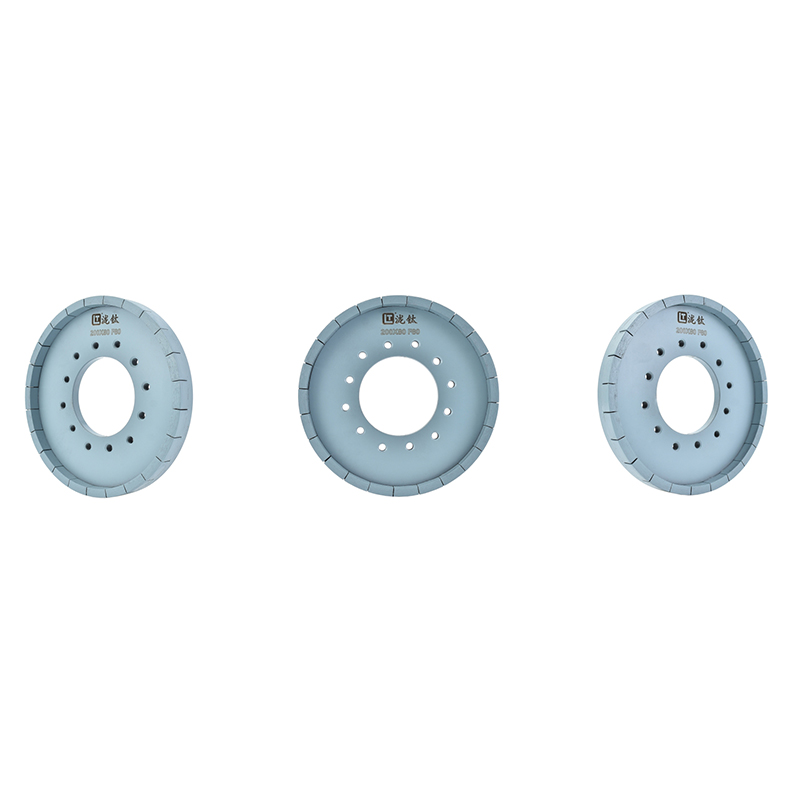

OEM Factory for Cutting Rigid Foam With Circular Saw - Diamond Squaring Wheel(segment) – JIAYAN

OEM Factory for Cutting Rigid Foam With Circular Saw - Diamond Squaring Wheel(segment) – JIAYAN Detail:

After the diamond calibrating roller processes the porcelain tile, producing a smooth surface with fixed thickness, the diamond segment grinding wheel can perform milling with excellent efficiency. It can be used for big size glaze ceramic tiles,porcelain tiles and polished porcelain tiles.Diamond dry edging wheel is mainly used for rough grinding, fine grinding and trimming of polished tiles, antique tiles and microcrystalline tiles. It mainly has the following characteristics: no black edge, good sharpness, long service life, low noise, Fast heat dissipation and less dust. It is very good to ensure the verticality and size requirements of the processed products, and will not collapse or collapse. The production process is strictly controlled and the product quality is stable. Choose reasonable formula and particle size matching for different brick quality. Products with various installation sizes can be manufactured according to customer requirements.

1.Dry and wet dual-use operation is convenient for dry grinding without burning the wheel

The service life of single-layer brazed diamond products is 2~3 times that of electroplated products. When cutting stone, dry grinding can be done without adding water, and the service life of single-layer brazed diamond products is longer. The grinding efficiency of single-layer brazed diamond products is 1~2 times that of electroplated products.

2.The grinding speed is fast and the work efficiency is effectively improved

Brazed diamond products do not delaminate or drop teeth during use, and the performance is safe and stable,It will not cause secondary pollution to the environment during use, and is a national green product,This product is made of imported diamond, super wear-resistant

3.Usage

The abrasive tool is used for processing granite, marble, concrete, ceramic tile, glass-ceramic, etc. 39353 The production formula of the improved composite bottom material of diamond grinding stone developed by Zhongyuan Institute of Technology is the processing technology of diamond grinding tools. The new formula process eliminates the phenomenon of bending (Bend) deformation, cracks, and delamination during high-temperature sintering, and ensures product quality. A new composite bottom material for diamond grindstones that can effectively prevent bending deformation, cracks or delaminations from existing diamond grindstone production technologies.

| DESCRIPTION | SPECIFICATION | WIDTH | HEIGHT |

| DIAMOND SQUARING WHEEL(SEGMENT)

|

Φ200 | 10 | 13 |

| Φ250 | 10 | 13-16 | |

| Φ300 | 12 | 14-16 |

Product detail pictures:

Related Product Guide:

Being supported by an highly developed and specialist IT team, we could give technical support on pre-sales & after-sales service for OEM Factory for Cutting Rigid Foam With Circular Saw - Diamond Squaring Wheel(segment) – JIAYAN , The product will supply to all over the world, such as: Monaco, Ecuador, Burundi, With excellent products, high quality service and sincere attitude of service, we ensure customer satisfaction and help customers create value for mutual benefit and create a win-win situation. Welcome customers all over the world to contact us or visit our company. We will satisfy you with our professional service!

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!